Recently, the team at CCG installed its very first HACS (Hot Aisle Containment System). The project was headed by Foreman and Electronic System Technician Tom Bowen alongside Tech John Moore. The design was validated by regional Chatsworth representatives during the installation. Keep reading below to find out more about how a Hot Aisle Containment System works and what are the benefits.

Hot aisle containment configurations are generally installed in large data centers that generally would be producing an excess of heat which could cause issues for the equipment if cooling is not done correctly.

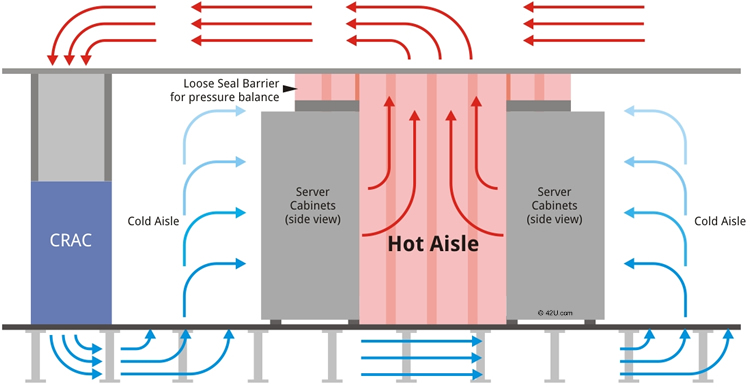

A basic explanation of a hot aisle containment setup is the “hot aisle” trapping hot air that is exhausted from any server equipment to feed and then sending that hot air back to the AC unit for the air to be repurposed into cooler air that will cool the network electronics. Any large data center has some type of cooling mechanism for all their equipment and chances are they have a HACS.

In December, CCG installed a HACS system at a Community College in Maryland. Alongside Chatsworth Engineers, Cody Wasmer (not pictured) and John Thompson (bottom right), techs Tom Bowen and John Moore built out the containment system within a matter of days.

The specific kit that the HACS system was built off of is Chatsworth part 33000-E02 alongside accessory parts 32770-E01 (Door Assembly), 32875-701 (Template), 32805-E01 (Mounting Bracket), 33002-E01 (Blanking Panel), 39208-E03 (Front Seal), 39209-E16 (Side Seal), and a 33001-001 (Flute Cutter).

Sources Used: